Improve capacity utilization, reduce total costs and accelerate digital transformation for customers.

Become the world's leading digital operations partner connecting manufacturing and logistics

Guided by customer needs, we continue to provide solutions and services that exceed expectations.

Leveraging our strengths in big data analysis and intelligent scheduling, our business has expanded into manufacturing and production.

Rich practical experience in the industry, covering the entire chain of scenarios from warehousing, transportation to terminal delivery, can be quickly implemented and solve actual pain points.

Accurate production planning, inventory control, and equipment utilization analysis help companies maintain stable output and cost control in a volatile environment.

With modular and scalable solutions, we can meet the customized needs of enterprises of different sizes, shorten the launch cycle, and reduce implementation risks.

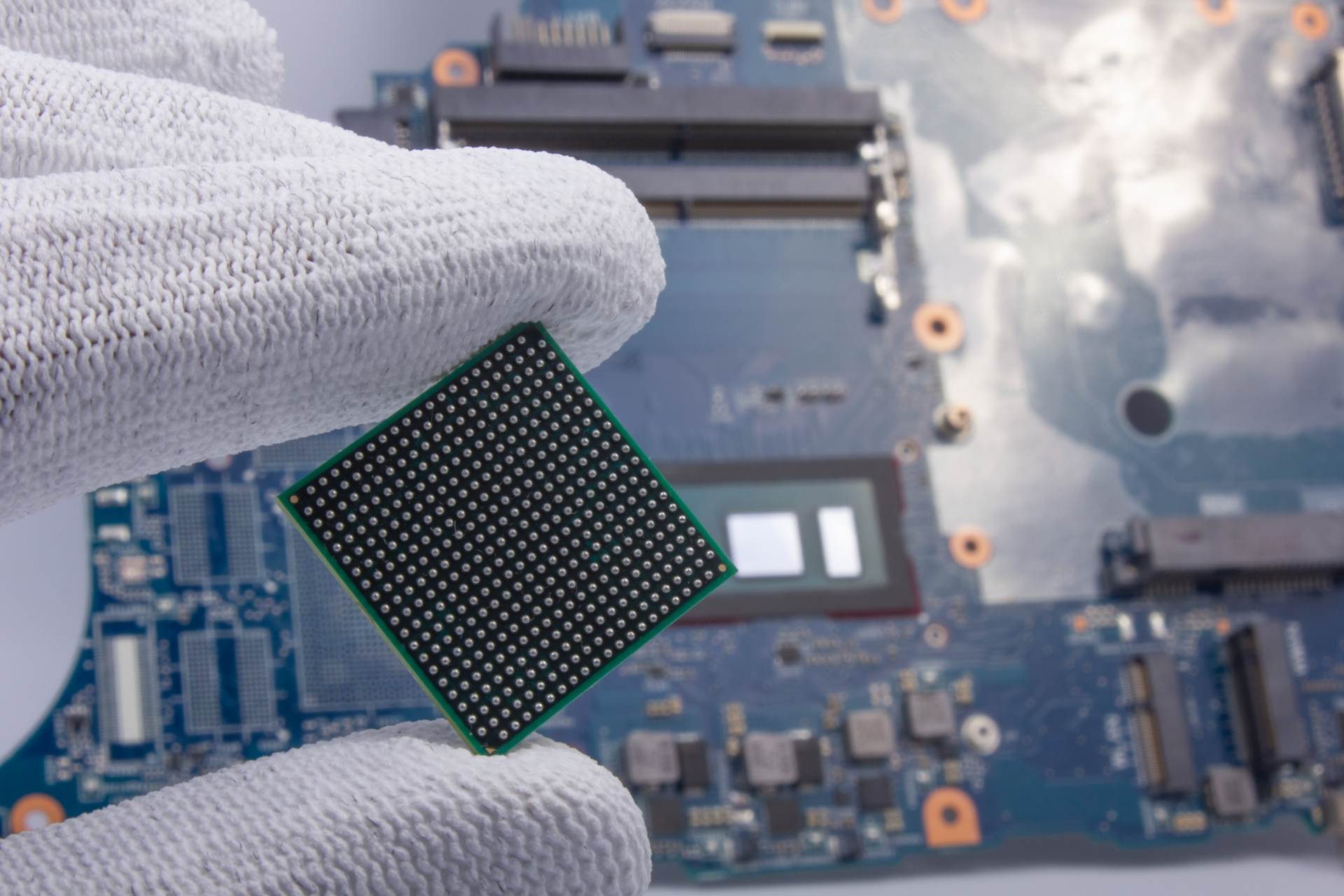

Our company specializes in the development and optimization of databases and backend systems, with a long history in the logistics sector, accumulating extensive experience in supply chain and process management. Leveraging our expertise in big data analysis and intelligent scheduling, our services have expanded into manufacturing and production, encompassing SMT production line development, production process optimization, and capacity planning. By deeply integrating big data technology with production management, we provide clients with precise production planning, inventory control, and equipment utilization optimization solutions, helping factories achieve efficient operations and cost control.

We use end-to-end data-driven solutions to help companies quickly implement and continuously optimize production and logistics.

We provide full-link services from demand analysis, architecture design, to implementation and operation and maintenance optimization.

High-performance design, scalable architecture, data governance and security control of databases and backend systems.

Real-time monitoring, data visualization and early warning mechanisms help management gain quick insights and make decisions.

Standardized components + modular architecture can be quickly combined into customer-specific solutions.

BOM/DFM review, production volume and product mix analysis.

Cycle time calculation, workstation balance, equipment list, budget and floor plan.

Equipment delivery coordination, calibration, basic procedure setup.

DOE experiments, curve optimization, placement library fine-tuning, and FPY target achievement.

SOP documentation, maintenance plans, training, KPI reports.

If you need more information or technical support, please feel free to contact us. We will provide the most suitable solution based on your needs to help you achieve a comprehensive improvement in production efficiency.

Beat analysis, feeder logistics, steel mesh and reflow oven matching, ESD and material flow design.

JUKI (RS, LX, KE series), Yamaha (YSM, YG series), printers, SPI/AOI, reflow ovens (Mancorp, Takamura).

Solder paste window setting, reflow curve optimization, placement library establishment, and feeder layout optimization.

"Your company's data-centric solutions, combined with industry experience and algorithmic capabilities, have enabled us to achieve continuous improvements in production planning and inventory management. Training and knowledge transfer have also empowered our team."

"In a multi-factory scenario, we've implemented a unified operations platform and real-time reporting, increasing production line utilization by 8% and significantly reducing material shortages. Your team's professionalism and swift implementation have helped us achieve a key breakthrough in our transformation from traditional operations to digitalization."

“Through end-to-end data-driven solutions, we have achieved rapid implementation and continuous optimization of production and logistics.”

If you need further information about specific services or other questions, please feel free to contact us!

By deeply integrating big data technology with production management, we provide customers with precise production planning, inventory control and equipment utilization optimization solutions, helping factories achieve efficient operations and cost control.

Copyright © 2025 XENON ELECTRONICS LIMITED