This article focuses on the comprehensive service matrix our company provides, encompassing production line planning, equipment selection, installation and commissioning, process optimization, and training. We demonstrate how our end-to-end delivery capabilities help customers achieve rapid implementation and stable operations.

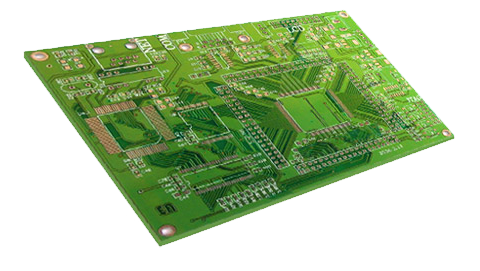

Production Line Planning and Layout:

– Cycle time analysis, feeder logistics design, stencil and reflow oven matching, ESD and material flow design, ensuring full-chain coordination from material to equipment.

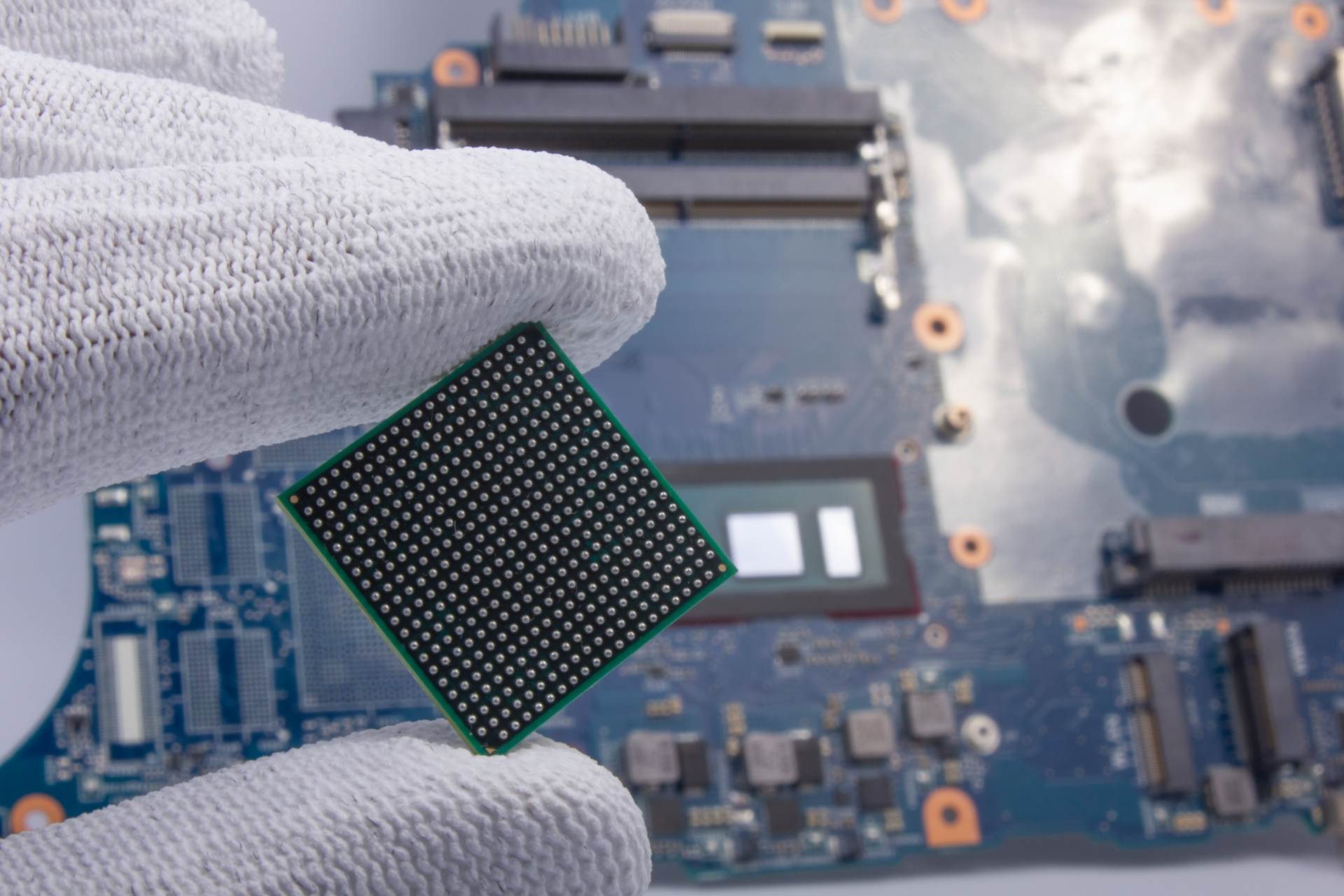

Equipment Selection:

Covering core equipment and tools: JUKI (RS, LX, KE series), Yamaha (YSM, YG series), printers, SPI/AOI, reflow ovens (Mancorp, Takamura), etc., customized based on factory scale and process requirements.

Installation and Commissioning:

Acceptance testing, basic program setup, NPI ramp-up, first article confirmation, and GR&R analysis ensure rapid and stable new line launch.

Process Optimization:

Solder paste window setting, reflow profile optimization, placement library establishment, and feeder layout optimization improve yield and production efficiency.

Training Services:

Operator training and certification, maintenance procedures, and quick-change operation guides ensure knowledge retention and continuous improvement.

Delivery Features:

End-to-end processes, standardized execution, and flexible customization combine to emphasize traceability and rapid iteration, helping customers achieve transformation with minimal risk.

Through our systematic service portfolio and professional on-site execution capabilities, we help customers maintain competitiveness in a rapidly changing market environment and achieve stable and efficient production operations.