As global manufacturing moves toward a new era of intelligence, our team, with databases and backend systems at its core, is deeply engaged in logistics and supply chain management, gradually expanding into manufacturing and production. Through big data analysis and intelligent scheduling, we provide clients with precise production planning, inventory control, and optimized equipment utilization, helping factories achieve efficient operations and cost control.

We specialize in database and backend system development and optimization, and have long been immersed in logistics and supply chain management. By integrating big data analysis and intelligent scheduling, we extend our expertise to the entire manufacturing chain.

Core Capabilities:

Data-Driven Production Planning: Through data modeling and analysis, we enable capacity forecasting, scheduling optimization, and Material Requirements Planning (MRP/MRP-II) to effectively improve production line utilization.

Inventory and Equipment Optimization: Leveraging traceability and visual dashboards, we improve material turnover, mitigate shortage risks, and optimize equipment utilization.

Customer Value: We shorten lead times, reduce in-process costs, and improve yield and stability, providing factories with sustainable productivity solutions.

Industry Coverage:

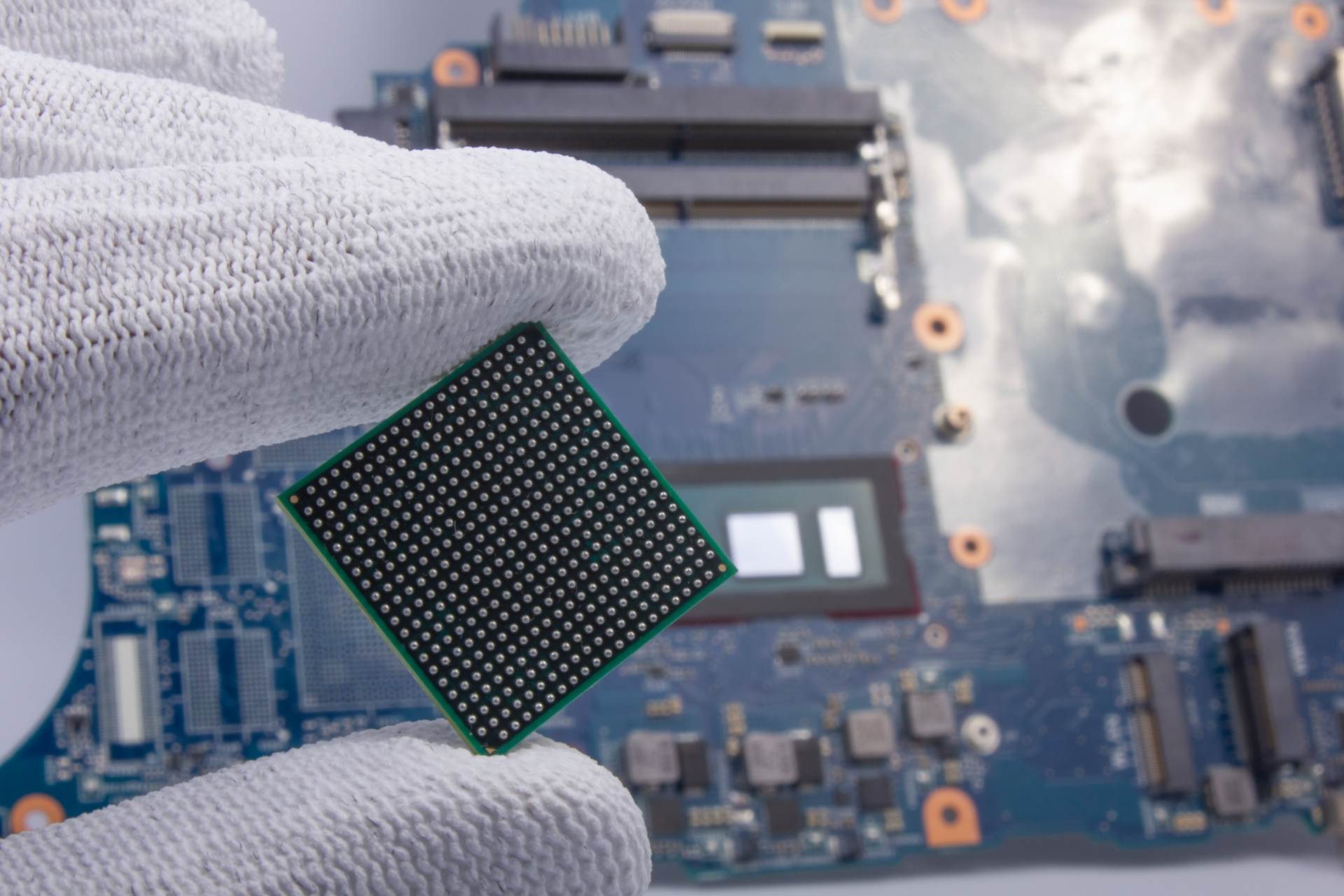

Our process portfolio ranges from SMT production line setup and production process optimization to capacity planning, serving scenarios closely related to manufacturing and logistics.

Driven by data and focused on customer needs, we continue to innovate at the intersection of big data, intelligent scheduling, and production management, bringing greater transparency, flexibility, and competitiveness to the manufacturing industry.