This article focuses on our technical approach to big data, intelligent scheduling, and traceability systems. Drawing on our familiarity with core platforms such as SMT equipment, inspection, and reflow ovens, we analyze how to transform these technological capabilities into significant operational value in actual production.

Technical Foundation:

– Database and Backend Systems: Based on data integration, cleansing, and modeling, they support real-time scheduling and plan optimization.

– Big Data Analysis and Intelligent Scheduling: Improve production line utilization and delivery reliability through predictive analysis, schedule optimization, and bottleneck identification.

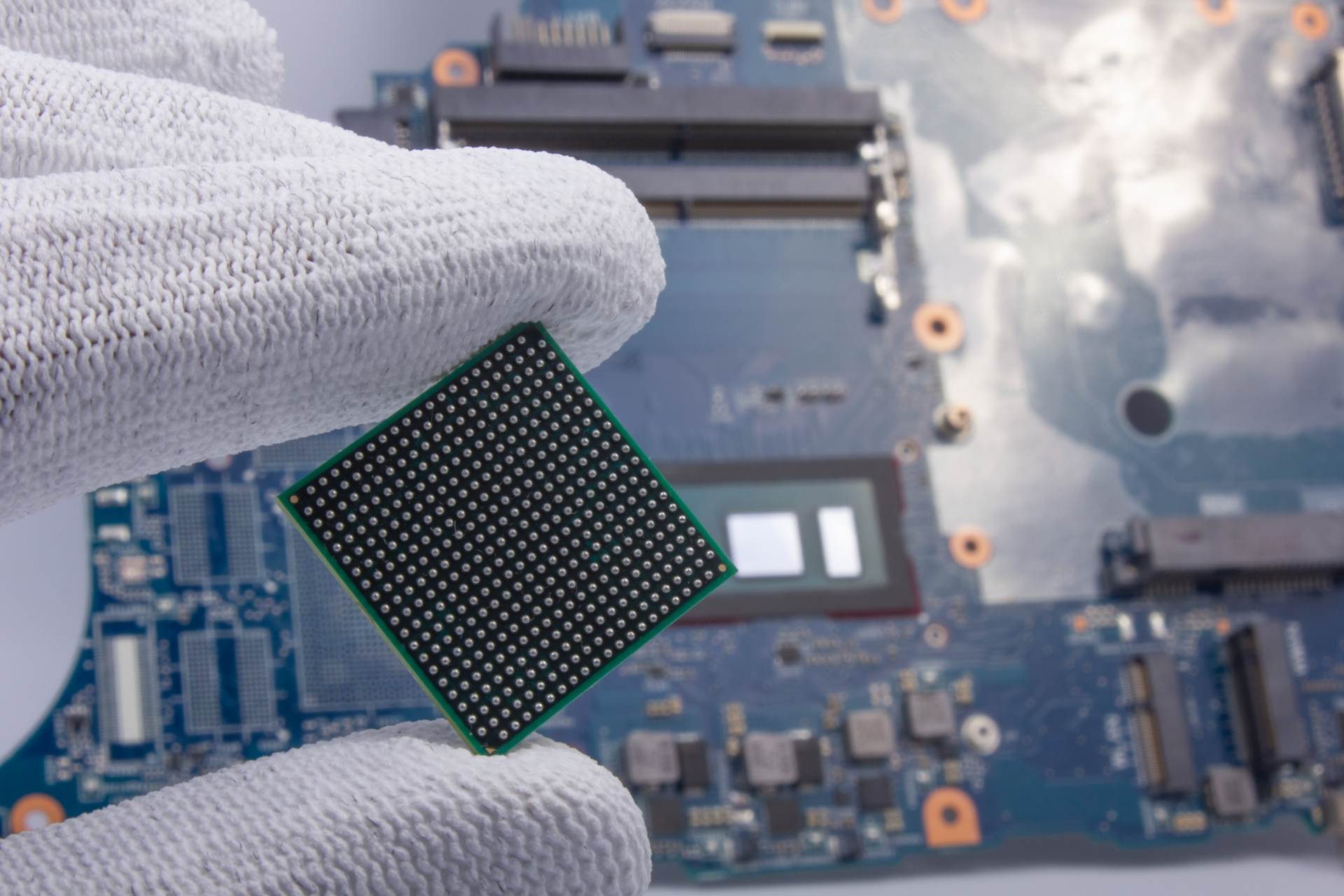

Key Platform Familiarity:

– Placement Machines: JUKI, Yamaha

– Inspection Equipment: SPI/AOI

– Reflow Oven: 7–10 Temperature Zone Configuration, Nitrogen/Air Process

– Traceability System: Feeder ID, Lot Traceability, and Barcode (Code 128/QR) Integration

Production Line Implementation Key Points:

– Line Planning: Comprehensive optimization of cycle time consistency, material flow, and ESD control. – Equipment Selection and Matching: Align with process windows, material properties, and yield targets to ensure efficiency and stability.

– Traceability and Quality Control: Enable full lifecycle traceability through real-time recording of barcode/batch information.

Industry Application Scenarios:

– High-mix/High-change Scenario: Fast line changeovers, flexible scheduling, and inventory savings.

– Quality-Sensitive Production: GR&R, First Article Confirmation, and Process Capability Analysis to improve stability.

– Supply Chains with Strict Traceability Requirements: Seamless integration of batches, barcodes, and IDs to meet compliance and traceability requirements.

Amid the wave of digital transformation in the manufacturing industry, we prioritize data-driven production management and combine our deep understanding of SMT and key manufacturing equipment to help customers transform complex processes and procedures into controllable productivity, driving factories toward more efficient, transparent, and sustainable operations.